DATA SHEET |

|

Formula: (CH2-CHCL) n n = 650~2100

Formula Weight: 40600~131250

Forms: White Powder. It is well compatable with Plasticisers, Organic Solvents and Fillers. It can be formed plastisol or organosol, and fabricated into diverse products.

Polyvinyl chloride paste resin (PVC) is a general purpose, medium molecular weight homopolymer designed primarily for the manufacture of PVC products. The resin product has a closely controlled particle size distribution and uniform porosity which results in excellent blending characteristics. This resin product exhibits good heat stability and good bulk density characteristics which makes this particular product especially suitable for the production of coating, molding and other general extrusion applications. This resin has good color and thermal stability.

This PVC resin product is well suited for a broad range of applications. This product is designed for flexible profile extrusion, calendared and extruded sheet, and blown film applications where consistent particle size distribution, and low contamination, flexible gels and residual VCM levels are important. This resin has excellent clarity, color, plasticizer absorption, and thermal stability.

Emulsion process which technology is from Mitsubishi Chemical Vinyl, Japan. PVC-resin is made with suspen-iltion polymerisation

|

Type

|

Properties

|

Main Application

|

|

P440

|

General purpose resin of medium weight, whose degree of polymerisation of about 1500 and K value of 73-75, with good transparancy, thermanl stability, water resistance and weather ability.

|

Nonfoamed and slightly foamed artificial leather, which can be used to spray and dye metal coating, glass fibres, dipping and general purpose products.

|

|

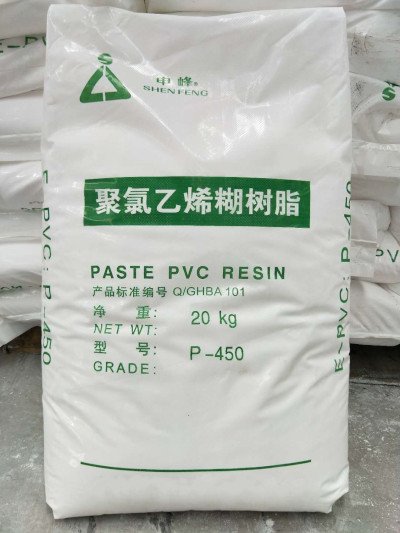

P450

|

Paste resin of low molecular weight, whose degree of polymerisation of about 1000 and K value of 65, with good foaminess and high speed coating ability, and content filler can be added.

|

Foamed layer of elastic floor, foamed artifical leather and wall paper.

|

|

|

|

|

Packaging : PE bags, net weight: 20kg each. Specification / Storage : Q/GHBA 101 / Stored in dry and ventilated place avoiding sun and moisture. Clean transportation facilities should beadopted to prevent rain. PVC dust is capable of propagating a secondary dust explosion. This potential can be reduced by good housekeeping, prevention of dust from process equipment, preventing accumulation of dust on over head horizontal surfaces and eliminating potential ignition sources. Avoid heat, flames, sparks, and other sources of ignition. Temperature / Storage Condition - 15-30 ° C / 40-75 % Relative Humidity ___________________________________________________________________________________ |

|

Item

|

P440

|

P450

|

|

≤ Mean Degree of Polymerization

|

1450 +/- 200

|

1000 +/- 150

|

|

≤ Brookfield Viscosity mpa.s DOP 60% 50r/m

|

5000

|

7000

|

|

≤ Volatile (including water) %

|

0.4

|

0.4

|

|

≤ Screen Residue (mesh 0.063mm) %

|

1.0

|

1.0

|

|

≤ Residue VCM mg/kg

|

10

|

10

|

|

≤ Impurity particle number

|

20

|

20

|

|

Safety Data Sheet / Heavy Metal Test ReportSafety Data Sheet / Heavy Metal Test Report / Technical Data sheet (TDS) - Manufacturers Safety Data Sheet (MSDS)

|

|

|

|

|

Description: Paste PVC Resin (Carbide-based) |

|

|

|

|

Health hazards: No danger to health under normal conditions of use. |

|

|

|

|

Skin: Wash with soap and water, if inflamed or irritated, consult a doctor. |

|

|

|

|

Special precautions: Do not inhale fumes |

|

|

|

|

Individual precautions: No special measures required. |

|

|

|

|

Manipulation: Respect normal rules for industrial hygiene. |

|

|

|

|

Technical measures: No special measures required if good respect of normal rules for industrial hygiene and security. |

|

|

|

|

Form: White Powder. Colour: White Vapour Pressure: Not applicable. |

|

|

|

|

Stability: Stable under normal conditions of use. Hazardous reactions: No hazardous reactions observed. |

|

|

|

|

No labeling is required for this material under EEC regulations - |

|

|

|

Contact

us by phone e-mail for any adhesive tape requirement

Web: www.printernational.co.uk ~ Tel: +44 (0)20 8050 8069 ~ E-mail: pr@printernational.co.uk