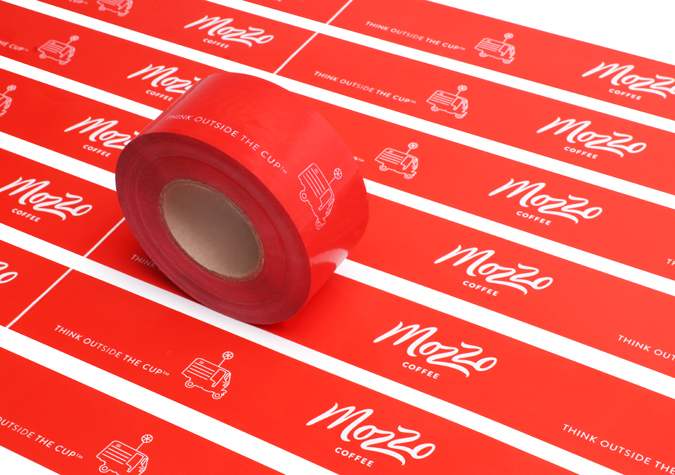

Available in standard or heavy duty, with a wide range of adhesives. Polypropylene tapes offer a wide selection of choice to optimise performance. Particularly suitable for semi and fully automatic case sealing.

|

|

Specifications

|

|

Carriers Thickness From

|

19 - 50mu

|

|

Adhesive Types

|

Noisy Acrylic, Low Noise Acrylic, Hot Melt, Solvent, Freezer Grade

|

|

Base Colour of Tape

|

White / Buff / Clear

|

|

Available Widths

|

12mm - 144mm

|

|

Available Lengths

|

Hand Rolls: 66m - 200m, Machine Rolls: 330m - 1056m

|

|

Lead Time

(10 days, 20 days) |

Yes

|

Polypropylene Printable Standard

Polypropylene Printable Silent Quality

Polypropylene Printable Hot Melt

Conditions of the printing machine:

Stereos:

Recommend is red Semperit or photopolymer. For Polypropylene Printable Hot Melt rubber stereos as used for PVC printing can also be used.

Working procedure:

The print rolls Polypropylene Printable Silent Quality should be stored at a temperature of 20 °C to 30 °C. before using them since this makes the unwinding lighter and enables a higher speed on the printing machine.

Where required heat up the printing cylinders. Install the ventilation system and make sure that the air in the drying tunnel has the right temperature. For Polypropylene Printable Hot Melt the drying tunnel must not be heated and ventilation has to be at maximum blowing capacity.

Though it is not imperative it is recommend that the tape is cleaned by mounting on the machine a piece of felt which rubs off possible dirty spots.

Adjust the friction of the winding system in order to avoid that the cores will be crushed.

The speed of the machine stays in close connection with the capacity of the ventilation and the drying tunnel.

In case the tape is insufficiently dried a problem with off-setting of the ink may arise. This can be noticed immediately.

The recommended speed of the machine is 80 to 100m. per minute.

In case there is a problem like ink transfer, too high unwinding resistance or tape splitting, this indicates that the drying is insufficient. In this case it is recommend that the speed of the machine be reduced or the performance of the drying tunnel will have to be improved.

To check the print quality, a method generally used is to place a roll in a refrigerator for 15 minutes. By means of a fast unwinding any problem will be noticed. In case there is a problem like ink transfer, too high unwinding resistance or tape splitting, this indicates that the drying is insufficient. In this case it is recommend that the speed of the machine be reduced or the performance of the drying tunnel will have to be improved. The problem may also be resolved by adding to the ink a solvent of isopropylic alcohol and heptane.

General Remarks:

During cold periods the inks should be stored at a temperature of 18 ° C to 20 ° C. In case the inks have become solid this can be resolved by immersing the container in a vessel with luke warm water.Before using the ink it has to be stirred thoroughly in order to obtain a perfect mix. Make sure that the containers of ink are well closed in order to avoid evaporation.At the end of the day the ink which remains in the containers of the machine should be placed back in the original container.During a stop of the production the heating system of the printing cylinder should be disconnected since a too high temperature will create problems with the proper winding of the tape.

Floodcoat printing has to be avoided.

Contact

us by phone e-mail for any adhesive tape requirement

Web: www.printernational.co.uk ~ Tel: +44 (0)20 8050 8069 ~ E-mail: pr@printernational.co.uk